Flexible through Know-how

The high number of ongoing orders in small and medium batch sizes with short delivery times requires an extremely flexible system for order processing. In a rough central planning, essential capacities for meeting the specified deadlines are estimated.

Machine occupancy and staff deployment are defined in the group concept. The production of the parts is carried out by highly qualified employees, who accompany the entire process from material withdrawal to despatch and are responsible for the production of the products in accordance with drawings. An effective management system ensures the use of safe and capable machines and testing equipment. Existing processes are continuously developed and improved in a comprehensive system.

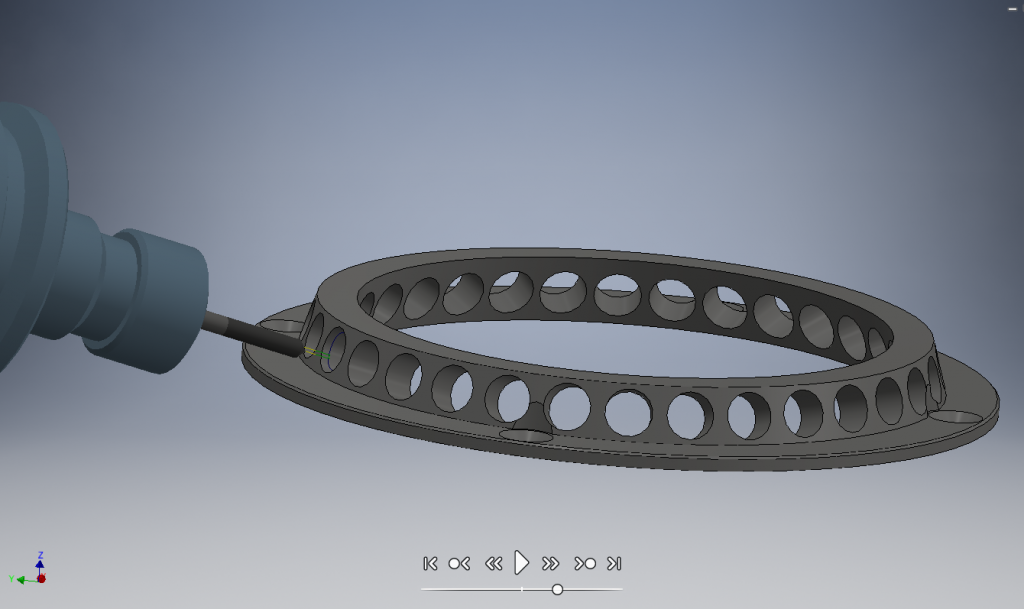

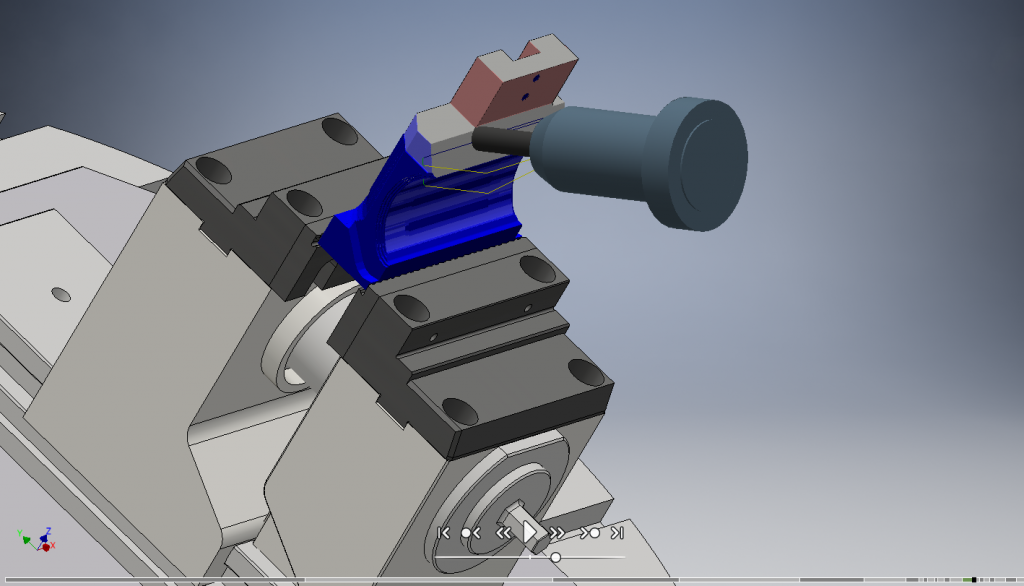

Turning and rotary milling up to Ø 360 mm and 1,250 mm turning length (chuck), up to Ø 101 mm (clamp)

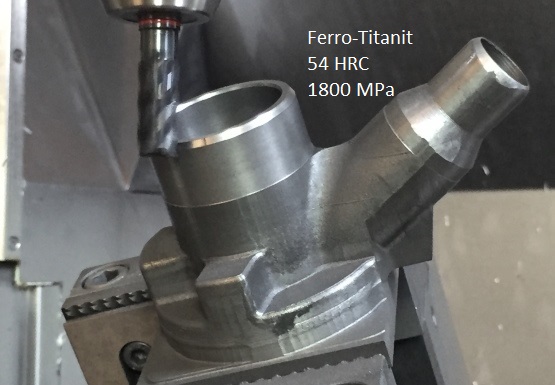

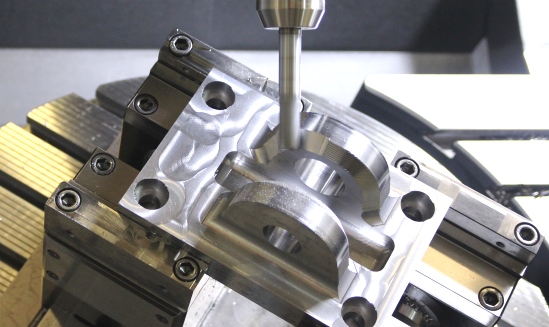

3 to 5-axis (simultaneous) milling up to 2,000 mm x 800 mm

Wire EDM, grinding, welding, engraving

Assembly production

Surface coating, hardening, tempering, soldering (external)